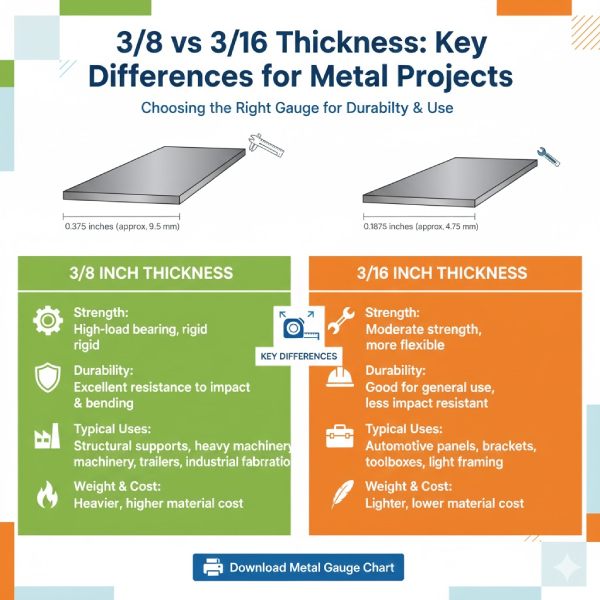

3/8 vs 3/16 Thickness: Key Differences for Metal Projects

Many people search for 3/8 vs 3/16 thickness when picking metal for building or making things. The main difference is size: 3/8 inch is twice as thick as 3/16 inch. 3/8 inch equals 0.375 inches, and 3/16 inch equals 0.1875 inches. Thicker metal is stronger and heavier. 3/8 inch works for heavy loads like frames. 3/16 inch fits lighter jobs like panels. Both come in steel, aluminum, and more. This guide explains strength, weight, uses, and costs for 3/8 vs 3/16 metal thickness. Choose the right one for safe and smart work.

Exact Measurements and Gauge Comparison

Understand 3/8 vs 3/16 thickness with clear numbers. 3/16 inch is 0.1875 inches thick. 3/8 inch is 0.375 inches thick – exactly double. In gauge terms, 3/16 inch is about 7 gauge for steel. 3/8 inch is around 0 gauge or plate. Gauges go down as thickness goes up. These are not gauge sizes but direct inches for plate metal. Sheet metal uses gauge more. For sheet metal 3/8 vs 3/16, 3/8 is plate, not sheet. Sheets stop around 1/4 inch. This helps when reading charts. Always check material type.

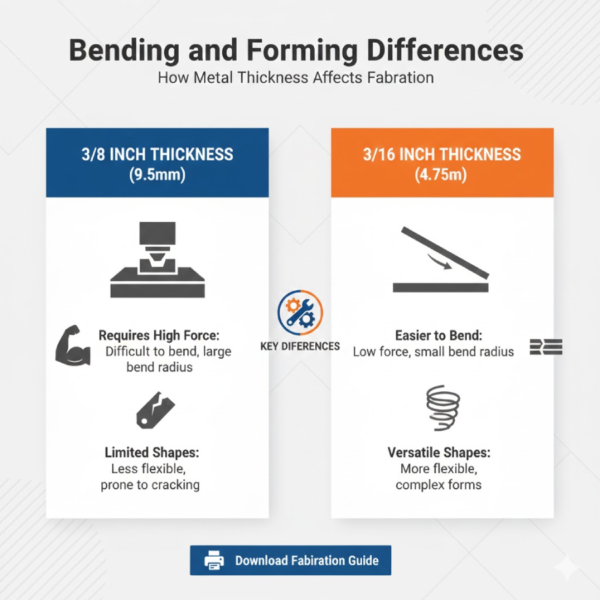

Bending and Forming Differences

Bending metal changes a lot between 3/8 vs 3/16 thickness. Thicker 3/8 inch steel needs a much larger bend radius to stop cracks. The rule is about three to four times the thickness for inside radius. So 3/8 inch needs over one inch radius. 3/16 inch bends tighter with smaller tools. This affects 3/8 vs 3/16 material in making boxes or brackets. Shops use big press brakes for thick plates. Thin sheet forms are easy on smaller machines. Heat can help bend thick metal but changes strength. Plan bends early to avoid weak spots. This 3/8 vs 3/16 plate steel forming tip saves rework.

Cutting and Machining Considerations

Cutting differs in 3/8 vs 3/16 thickness. 3/16 inch cuts fast with plasma or laser. It uses less power and makes clean edges. 3/8 inch needs stronger tools like oxy-fuel or waterjet for thick cuts. Saw blades wear quickly on plates. Machining like drilling takes more time on thick metal. Chips remove slower. This 3/8 vs 3/16 steel cutting guide helps shop time. Use coolant for heat control on thick pieces. Sharp tools last longer on thin.

Corrosion and Finish Options

Finish and protection vary with 3/8 vs 3/16 thickness. Thicker metal lasts longer outside because rust takes time to eat through. 3/8 inch plate holds paint or galvanize well for outdoor use. 3/16 inch needs good coating fast or rust starts quick. Powder coat works on both but covers thick edges better. This 3/8 vs 3/16 aluminum also applies – thick resists dents more. Clean surfaces well before finishing. The primer stops rust under paint.

Tolerance and Precision in Manufacturing

Precision changes in 3/8 vs 3/16 thickness. Plates like 3/8 inch have looser tolerances from mill rolling. It can vary a bit in flatness or thickness. Sheet in 3/16 inch sheet comes tighter and flatter. This affects 3/8 vs 3/16 metal thickness in tight fits. Machine after cut for exact parts on thick. Thin sheet fits as-is more often. Check specs when ordering.

Environmental and Recycling Impact

Thick metal uses more resources in 3/8 vs 3/16 thickness. 3/8 inch needs more raw ore and energy to make. But it lasts longer so replaces less often. Both recycle well – steel melts easy. This 3/8 vs 3/16 steel plate green view helps sustainable choice. Thin uses less but may wear out faster. Balance life span and material.

Safety Precautions for Handling

Safety is key with 3/8 vs 3/16 thickness. The thick plate weighs heavy and has sharp edges after cut. Use gloves and lifts to move 3/8 inch pieces. Thin sheet cuts skin easily too. Secure work to stop slips. Wear eye protection for sparks. This 3/8 vs 3/16 material handling keeps you safe on the job. Team lift for big sheets. Store flat to avoid tip.

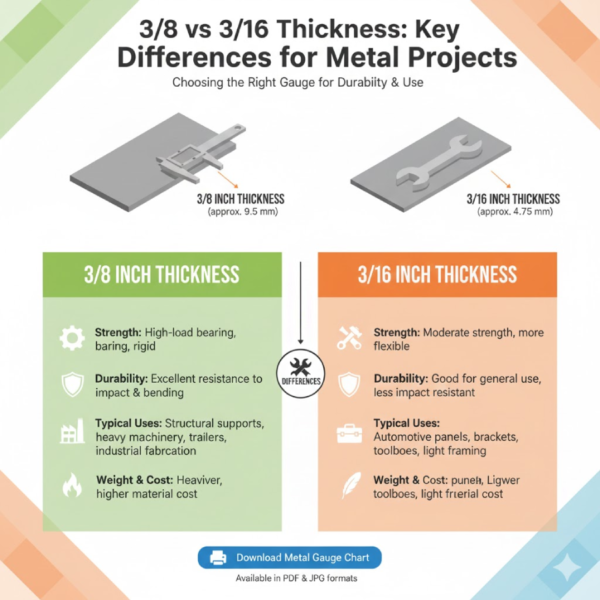

Strength and Load-Bearing Differences

Strength is a big reason to compare 3/8 vs 3/16 thickness. Thicker metal holds more weight. 3/8 inch steel can bear much heavier loads than 3/16 inch. For example, in beams, 3/8 inch bends less under pressure. It suits structural parts like brackets or bases. 3/16 inch works for covers or light frames. It flexes more but saves weight. Tests show 3/8 inch has double the stiffness in many cases. Use 3/8 vs 3/16 steel for safety in heavy jobs. Engineers calculate exact needs.

Weight and Material Use Impact

Weight changes a lot in 3/8 vs 3/16 thickness. 3/8 inch metal weighs twice as much per square foot as 3/16 inch. Steel at 3/16 inch is about 7.5 pounds per square foot. 3/8 inch is around 15 pounds. Aluminum is lighter overall. Heavy weight makes 3/8 inch harder to lift or ship. But it adds stability. Choose 3/16 inch for portable items. This affects 3/8 vs 3/16 aluminum in trailers or signs. Balance strength and ease.

Common Applications for Each Thickness

Pick based on job for 3/8 vs 3/16 metal thickness. 3/8 inch fits heavy duty like machine bases, truck frames, or building supports. It welds strong and lasts long. 3/16 inch suits body panels, enclosures, or decorative parts. It bends easy for shapes. In construction, 3/8 inch for floors, 3/16 for walls. This 3/8 vs 3/16 plate steel choice matters for cost and fit.

Welding and Fabrication Tips

Welding differs in 3/8 vs 3/16 thickness. 3/16 inch needs less heat and filler. It welds fast with lower risk of burn. 3/8 inch requires more power and pre-heat to avoid cracks. Multi-pass welds often needed. Bend radius is larger for thicker metal. 3/16 inch forms tight curves. This helps in 3/8 vs 3/16 material shop work.

Cost and Availability Factors

Cost rises with thickness in 3/8 vs 3/16 thickness. 3/8 inch uses more metal so prices higher. Supply varies – 3/16 inch more common in sheets. 3/8 inch often cut to order. Shop around for deals. This impacts 3/8 vs 3/16 steel plate budgets.

FAQ

What is the main difference in 3/8 vs 3/16 thickness?

The key in 3/8 vs 3/16 thickness is size and strength. 3/8 inch is 0.375 inches thick, double 3/16 inch at 0.1875 inches. Thicker means stronger and heavier. Use 3/8 for heavy loads, 3/16 for lighter. This 3/8 inch vs 3/16 inch affects projects big time1. Check needs first.

Which is stronger, 3/8 or 3/16 metal?

3/8 inch is much stronger in 3/8 vs 3/16 metal thickness. It holds more weight and bends less. Great for structures. 3/16 inch lighter but flexes more. This 3/8 vs 3/16 steel plate strength comparison helps safe choice.

When to use 3/8 vs 3/16 sheet metal?

Use 3/8 inch for heavy parts in 3/8 vs 3/16 sheet metal. 3/16 inch for panels or covers. Thicker for support, thinner for looks. This when to use 3/8 vs 3/16 sheet metal depends on load.

How much heavier is 3/8 compared to 3/16?

3/8 inch weighs about double 3/16 in 3/8 vs 3/16 thickness weight difference. Steel example: 15 vs 7.5 pounds per foot. Affects shipping and handling.

Is welding easier on 3/8 or 3/16 thickness?

Welding 3/16 inch is easier in 3/8 vs 3/16 thickness welding guide. Less heat needed. 3/8 requires more skill and time.

Conclusion

Choosing between 3/8 vs 3/16 thickness depends on strength2, weight, and job needs. 3/8 inch offers power for heavy work. 3/16 inch saves weight for lighter tasks. Measure your project and pick smart. What project are you planning with metal?

References

- Sheet metal conversion reference from Best Materials gauge chart. ↩︎

- Standard metal gauge and thickness chart from Metaltrone gauge chart PDF. ↩︎